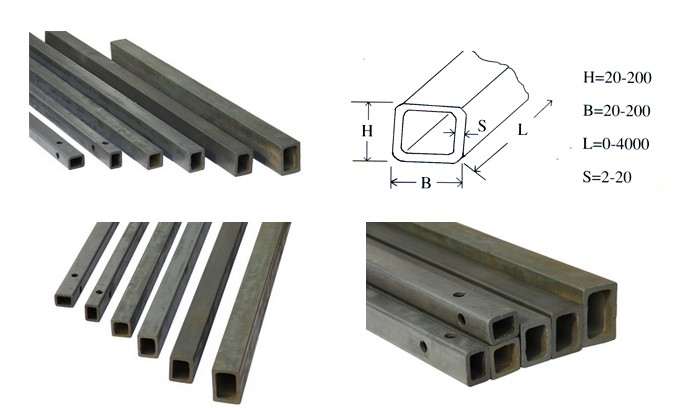

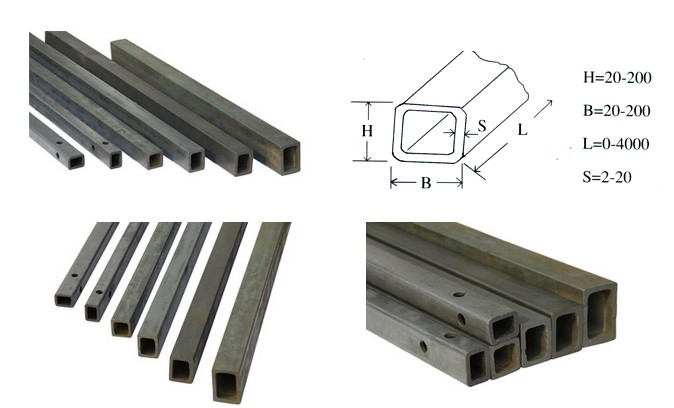

Refractory Silicon Carbide Rectangular Beam

Refractory Silicon carbide rectangular beam

Refractory Silicon carbide rectangular beam

1.Sintering Theory:

Reaction bonded SiC beam is made from α_SiC powder, graphite powder, mixing additives and organic adhesive agent.The mixture body is extruded and then filled into crucible with silicon powder. Sinter in a vacuum heating furnace at 1600 ~1800° C, the melt silicon powder reacts to the silicon in the body, finally from β-Sic due to the heat of reaction.

2. Product details:

Refractory Silicon carbide rectangular beam

1.Sintering Theory:

Reaction bonded SiC beam is made from α_SiC powder, graphite powder, mixing additives and organic adhesive agent.The mixture body is extruded and then filled into crucible with silicon powder. Sinter in a vacuum heating furnace at 1600 ~1800° C, the melt silicon powder reacts to the silicon in the body, finally from β-Sic due to the heat of reaction.

2. Product details:

Items |

Unit |

Data |

Max. Service temp |

ºC |

1380 |

Density |

g/cm3 |

3.02 |

Apparent Strength |

% |

<0.1 |

Bending Strength |

M pa |

250(20ºC) |

M pa |

280(1200ºC) |

|

Modulus of elasticity |

G pa |

330(20ºC) |

G pa |

300(1200ºC) |

|

Thermal conductivity |

W/m.k |

45(1200ºC) |

Thermal explanation |

K-1x10-6 |

4.5 |

Vickers-hardness |

G pa |

20 |

Acid-proof alkaline |

EXCELLENT |

|

Bearing Capacity of Beams |

||||||

|

Size of Section (mm) |

|

Concentrated Loading (kg.m/L) |

Uniformly Distributed Loading(kg.m/L) |

|||

|

B Side |

H Side |

B Side |

H Side |

B Side |

H Side |

|

|

30 |

30 |

5 |

74 |

74 |

147 |

147 |

|

30 |

40 |

5 |

117 |

95 |

235 |

190 |

|

40 |

40 |

5 |

149 |

149 |

298 |

298 |

|

50 |

50 |

6 |

283 |

283 |

567 |

567 |

|

50 |

60 |

6 |

374 |

331 |

748 |

662 |

|

50 |

70 |

6 |

473 |

379 |

946 |

757 |

|

60 |

60 |

7 |

481 |

481 |

962 |

962 |

|

80 |

80 |

7 |

935 |

935 |

1869 |

1869 |

|

100 |

100 |

8 |

1708 |

1708 |

3416 |

3416 |

|

110 |

110 |

10 |

2498 |

2498 |

4997 |

4997 |

The Bending Strength of RBSIC(SiSiC) Beams is 250MP, safety coefficient is 5.

Concentrated Loading =the Value in the Table Accordingly x 1/L,

Uniformly Distributed Loading = the Value in the Table Accordingly x 1/L。

We are offering any other kinds of kiln furniture and engineer ceramics ware on request.

【 Go Back 】 | 【 Close this window 】