1.High refractoriness.

2.Good thermal conductivity.

3.Small expansion coefficient.

4.High strength.

5.Ultra thin,energy saving.

Inquiry

|

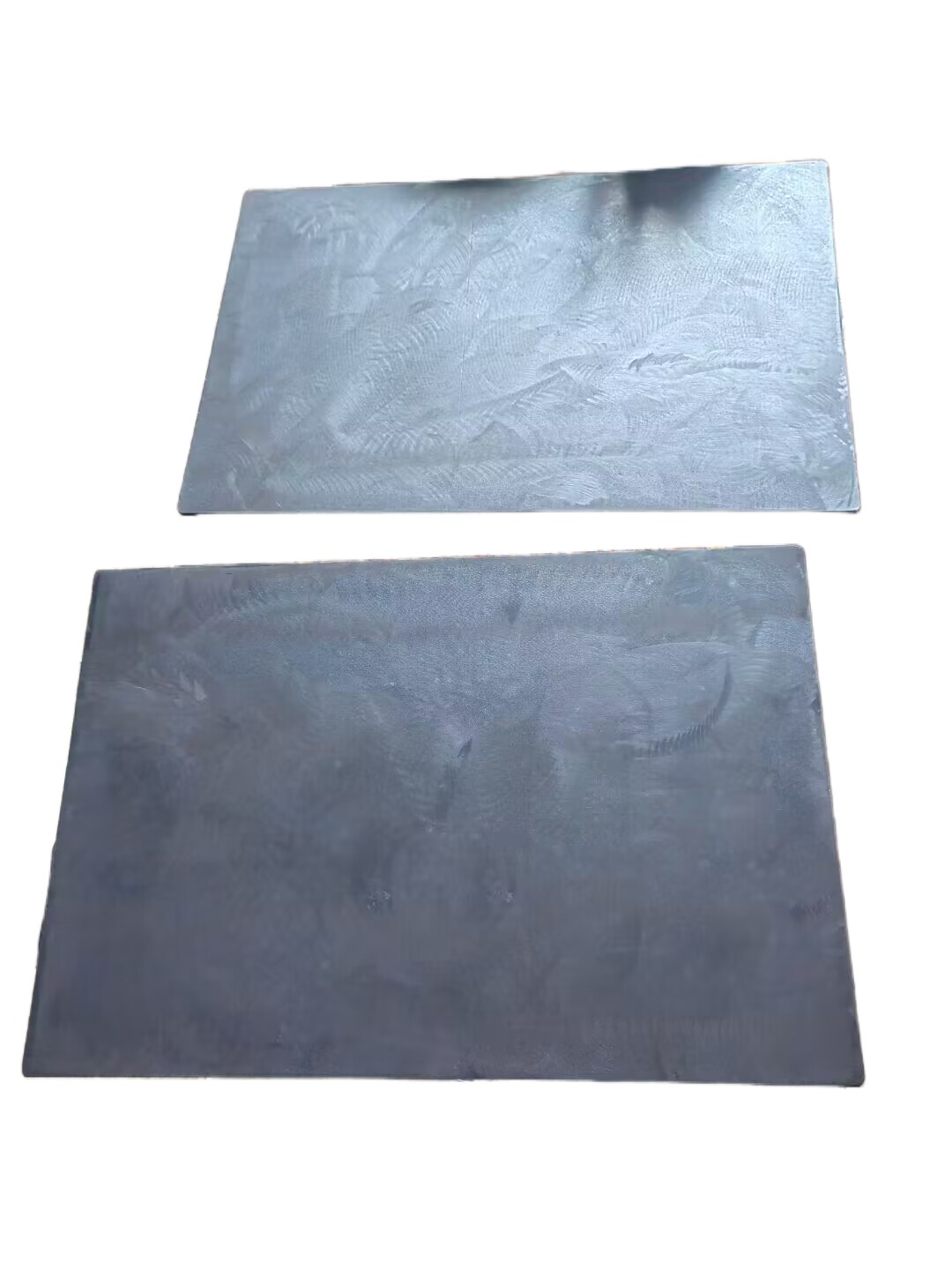

Silicon Carbide (SiC) wear-resistant plates are high-performance materials widely used in industrial fields that require high wear resistance, corrosion resistance, and high-temperature stability. Below is key information about silicon carbide wear-resistant plates:

1. Material Properties

-

High Hardness: Silicon carbide has a hardness second only to diamond, offering excellent wear resistance.

-

Corrosion Resistance: It exhibits strong resistance to chemicals such as acids and alkalis.

-

High-Temperature Stability: It maintains excellent mechanical properties even in high-temperature environments.

-

Low Thermal Expansion Coefficient: It provides good dimensional stability under temperature variations.

-

High Thermal Conductivity: Suitable for applications requiring heat dissipation.

2. Application Areas

-

Mining and Metallurgy: Used for conveyor liners, wear-resistant pipelines, etc.

-

Chemical Industry: Used for corrosion-resistant equipment linings, reactors, etc.

-

Power Industry: Used for wear-resistant components in flue gas desulfurization equipment.

-

Ceramics and Glass Industry: Used for wear-resistant parts in high-temperature kilns.

-

Mechanical Manufacturing: Used for high-wear-resistant mechanical components.

3. Manufacturing Processes

-

Hot Pressing Sintering: Produces high-density, high-strength silicon carbide plates under high temperature and pressure.

-

Reaction Sintering: Utilizes the reaction between silicon and carbon to form silicon carbide, suitable for manufacturing complex shapes.

-

Chemical Vapor Deposition (CVD): Used to produce high-purity, high-performance silicon carbide materials.

4. Advantages

-

Long Service Life: Offers extended lifespan in harsh environments.

-

Low Maintenance Costs: Reduces replacement and downtime.

-

High Efficiency: Improves production efficiency and reduces energy consumption.

5. Considerations

-

Brittleness: Silicon carbide is relatively brittle and should be protected from strong impacts.

-

Cost: The complex manufacturing process results in higher costs.

-

Processing Difficulty: Its high hardness makes processing challenging, requiring specialized tools.

Silicon carbide wear-resistant plates, with their excellent properties, are widely used in various industrial fields. When selecting, it is important to consider their characteristics and costs based on specific requirements.

Technical parameters

|

Item |

Unit |

Data |

|

Max temperature of application |

℃ |

1380 |

|

Density |

g/cm3 |

≥3.02 |

|

Open porosity |

% |

<0.1 |

|

Bending strength |

Mpa |

250(20℃) |

|

Mpa |

280(1200℃) |

|

|

Modulus of elasticity |

Gpa |

330(20℃) |

|

Gpa |

300(1200℃) |

|

|

Thermal conductivity |

W/m.k |

45(1200℃) |

|

Coefficient of thermal expansion |

K-1×10-6 |

4.5 |

|

Rigidity |

|

13 |

|

Acid alkaline-proof |

|

Excellent |

Property:

→Superior high temperature resistance,wear resistance and oxidation resistance.

→Excellent straightness,less than 1‰.

→High uniformly distributed loading capacity,more than 4997 kg.m/L.

→OEM accepted.

→Easy to install.

→Various shape accepted,Germany imported technology and materials.

→Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane).

Packaging & Shipping

The packing type of silicon carbide product is plywood box with plastic foam inside.

Email:masonvicky@hotmail.com skype:masonvicky